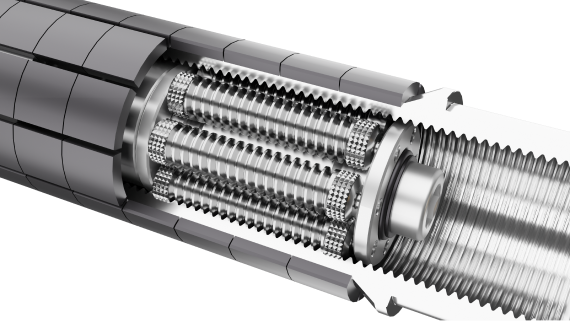

Comparing to traditional ball-screw actuators, the roller-screw Diakont units are much more durable an can be operated much longer. Thanks to special hardening technologies of roller-screws, high-quality of materials processing and robust design, Diakont actuators withstand higher loads during longer time. Overall lifetime can be increased up to several time compared to ball screw solutions.

Long Lifetime

Compact Design

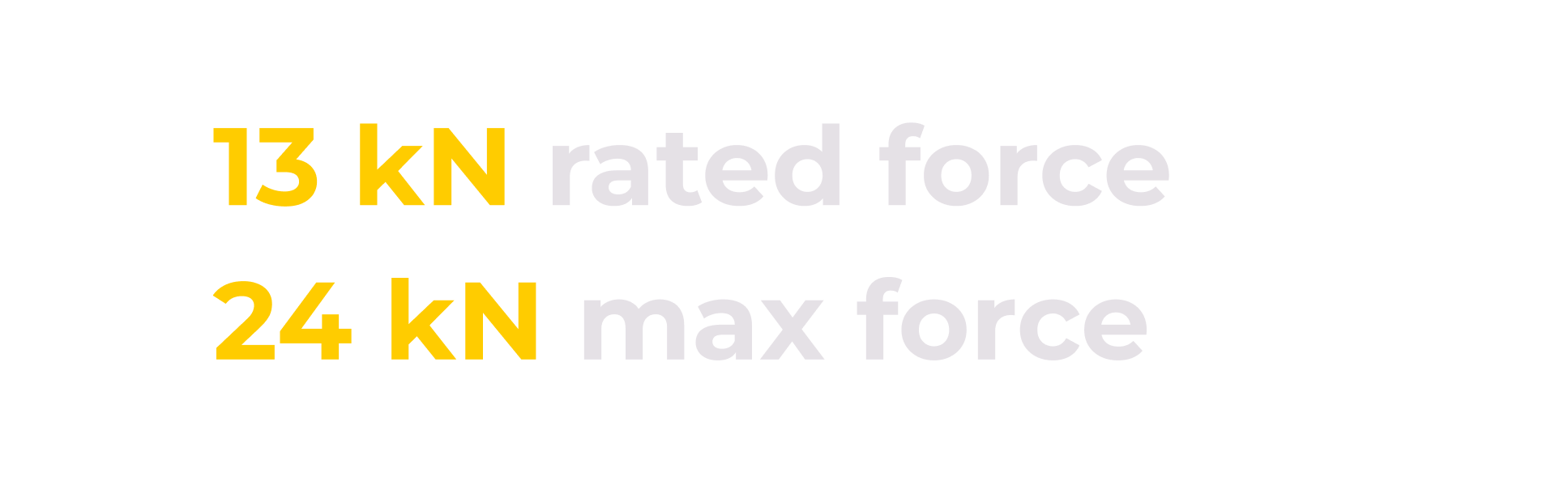

High Force

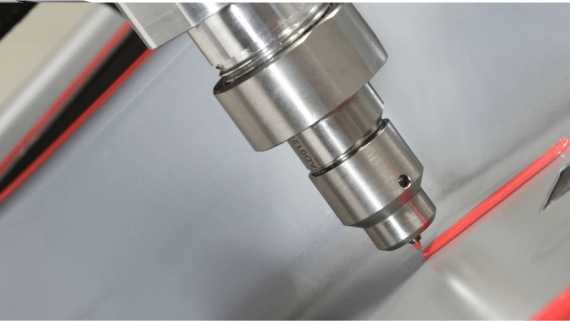

Great Accuracy

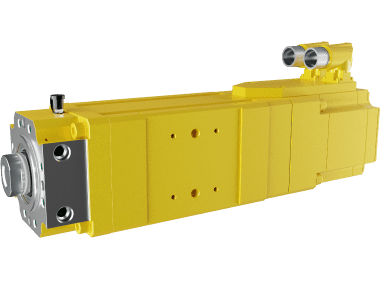

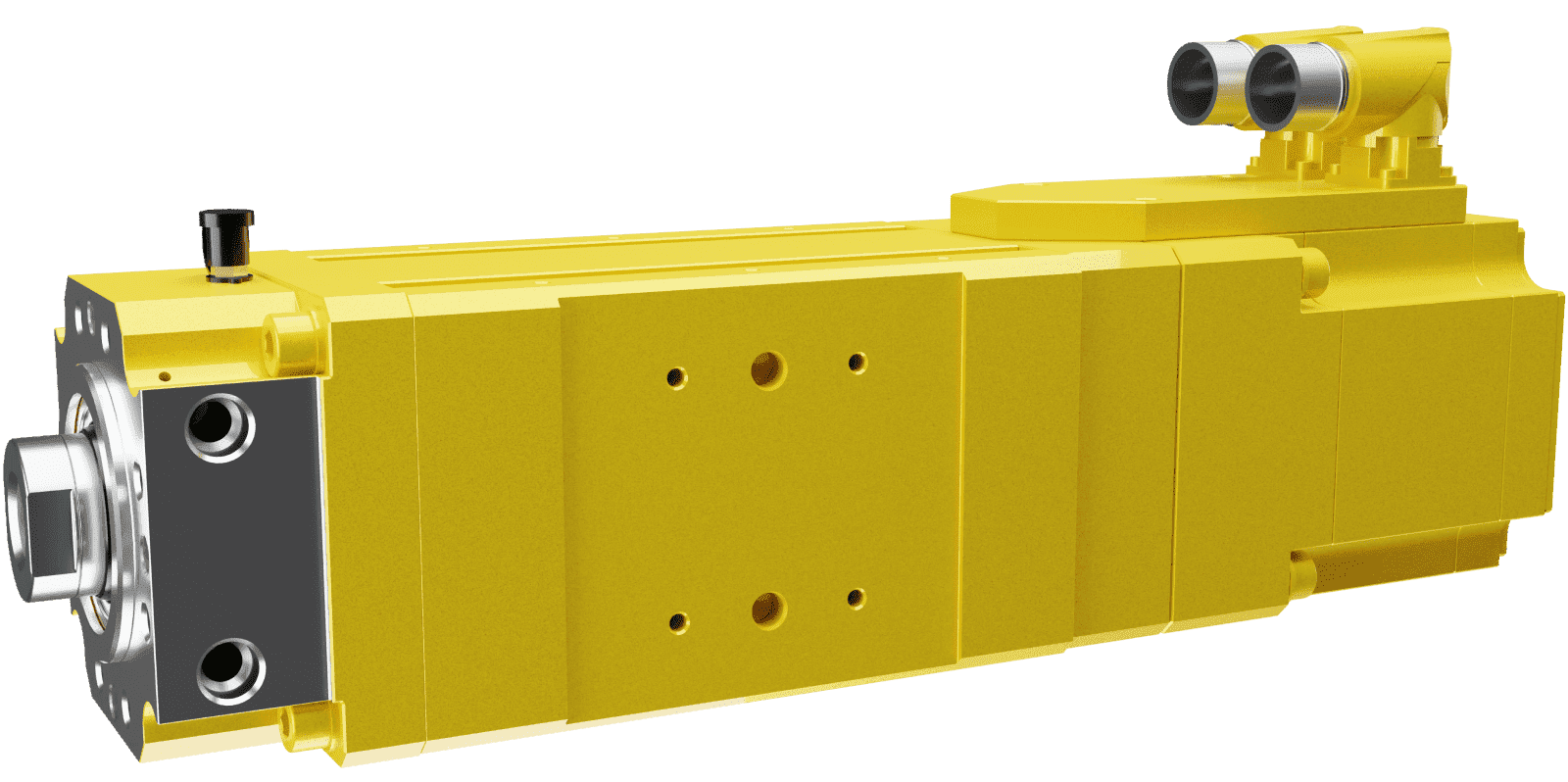

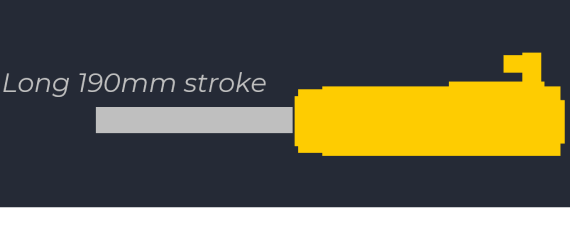

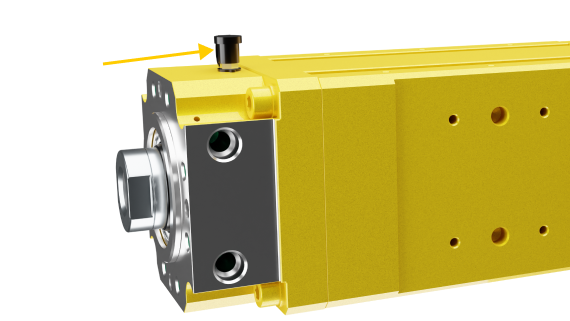

Electromechanical roller-screw actuator for dosing applications with 2.5 mm/rev pitch and long 190mm stroke

Max force: 24 kN

Max speed: 150 mm/s

Frame size: 99x99 mm

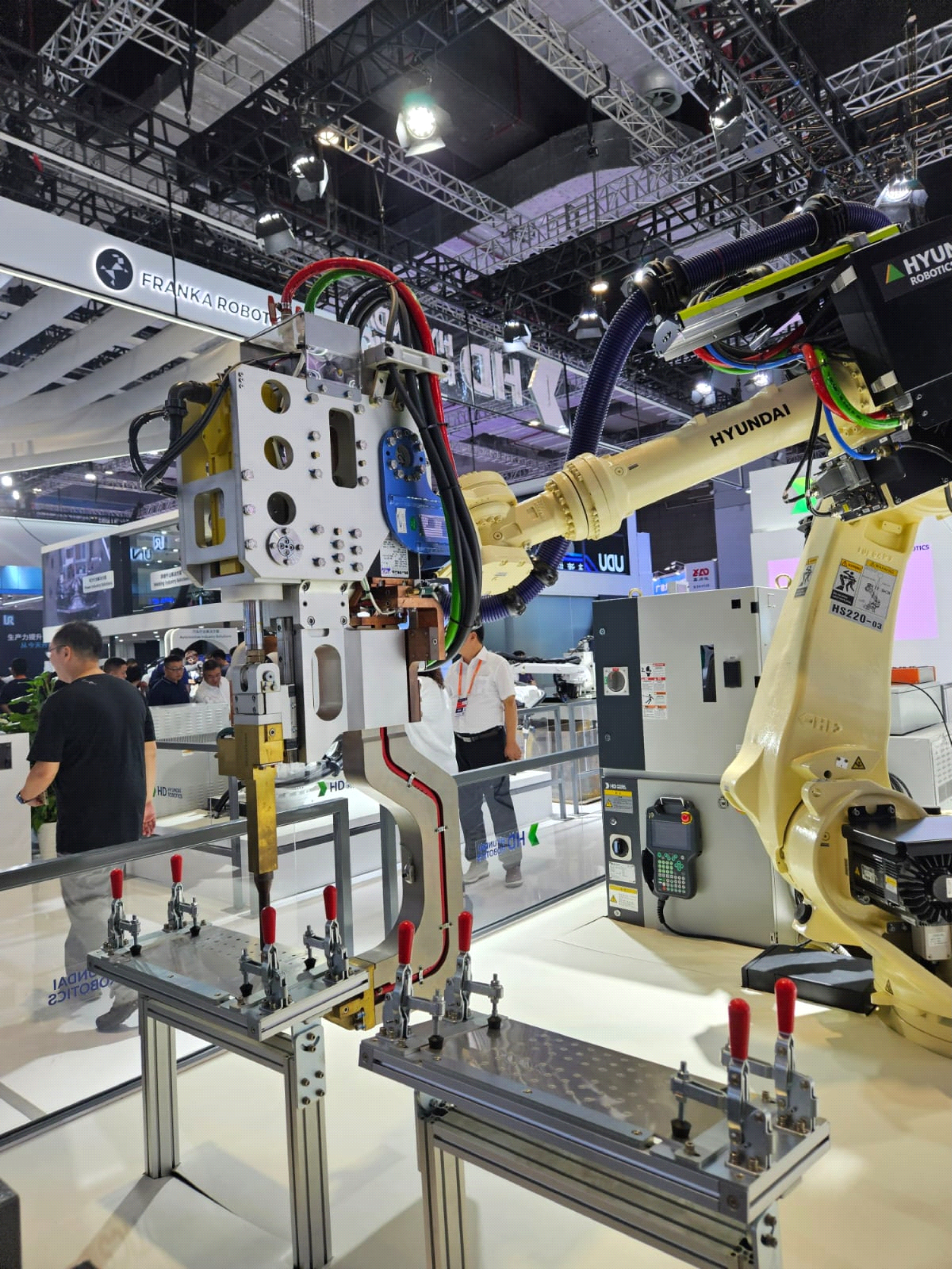

actuators bring for

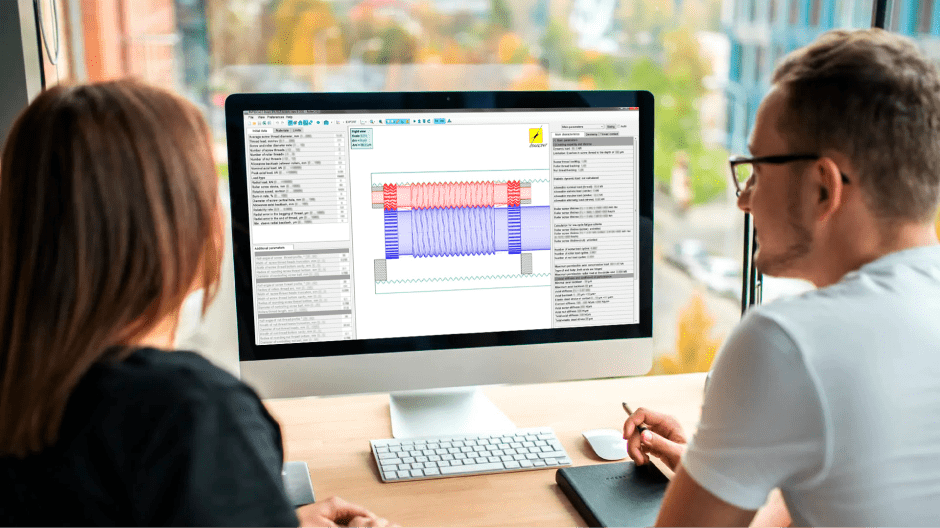

The consistently high quality of applying adhesives and sealants to the surface of the parts is ensured by high positioning accuracy, which is achieved by 2.5 mm roller screw and high precision of encoder. It provides high level of control over dispensing process and results in high quality of the adhesive seams.

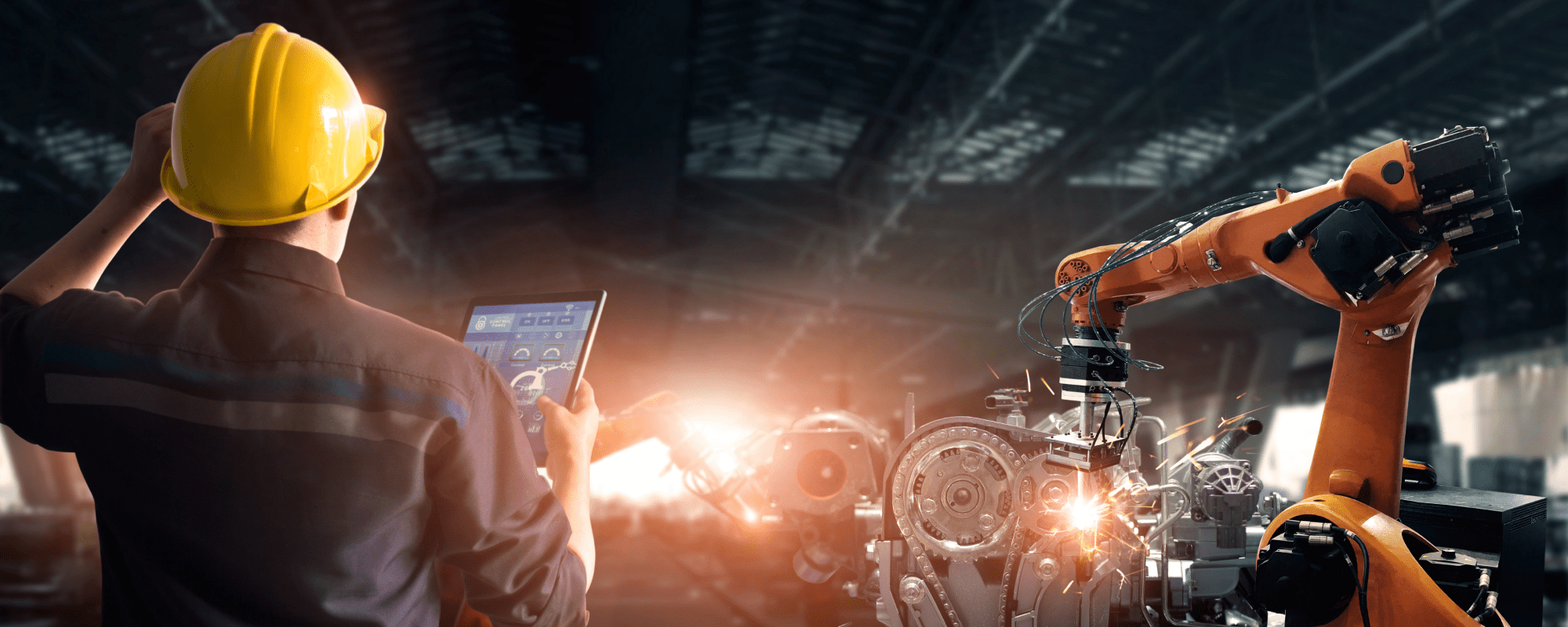

Thanks to a more powerful motor and a smaller transmission ratio, the Diakont roller-screw actuator can be used for higher loads, expanding the range of operating pressures of the dispenser.

High force range combined with a long stroke of 190 mm allows to use DA99-D22 actuator in a variety of applications, which allows to save costs on the necessity to have different models for different dosing units and shot meter sizes and volumes.

Diakont actuators are equipped with a digital memory containing the serial number and information about the feedback sensor and actuator parameters, that are automatically read by the customer's control system. This makes it possible to connect or replace the actuators without the need to manually configure the control system.

Thanks to the placement of the grease adding port on the front flange, Diakont actuators provided the ability to add lubricant regardless of the position of the dispenser rod. With this feature it is possible to conduct maintenance at any stage of the production cycle and without any preparation operations.

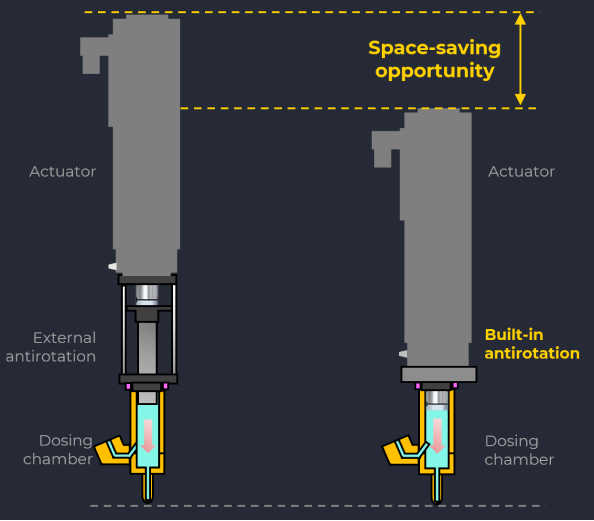

Diakont special built-in antirotation allows to keep the sealing protection so that no leakages or contaminants get inside of the housing while round shape of the rod is maintained.

With such an antirotation adapted to an adhesive chamber and dosing unit designs it would be possible to seriously decrease dimensions of the dosing unit and make it easier for the robot to reach confined areas.