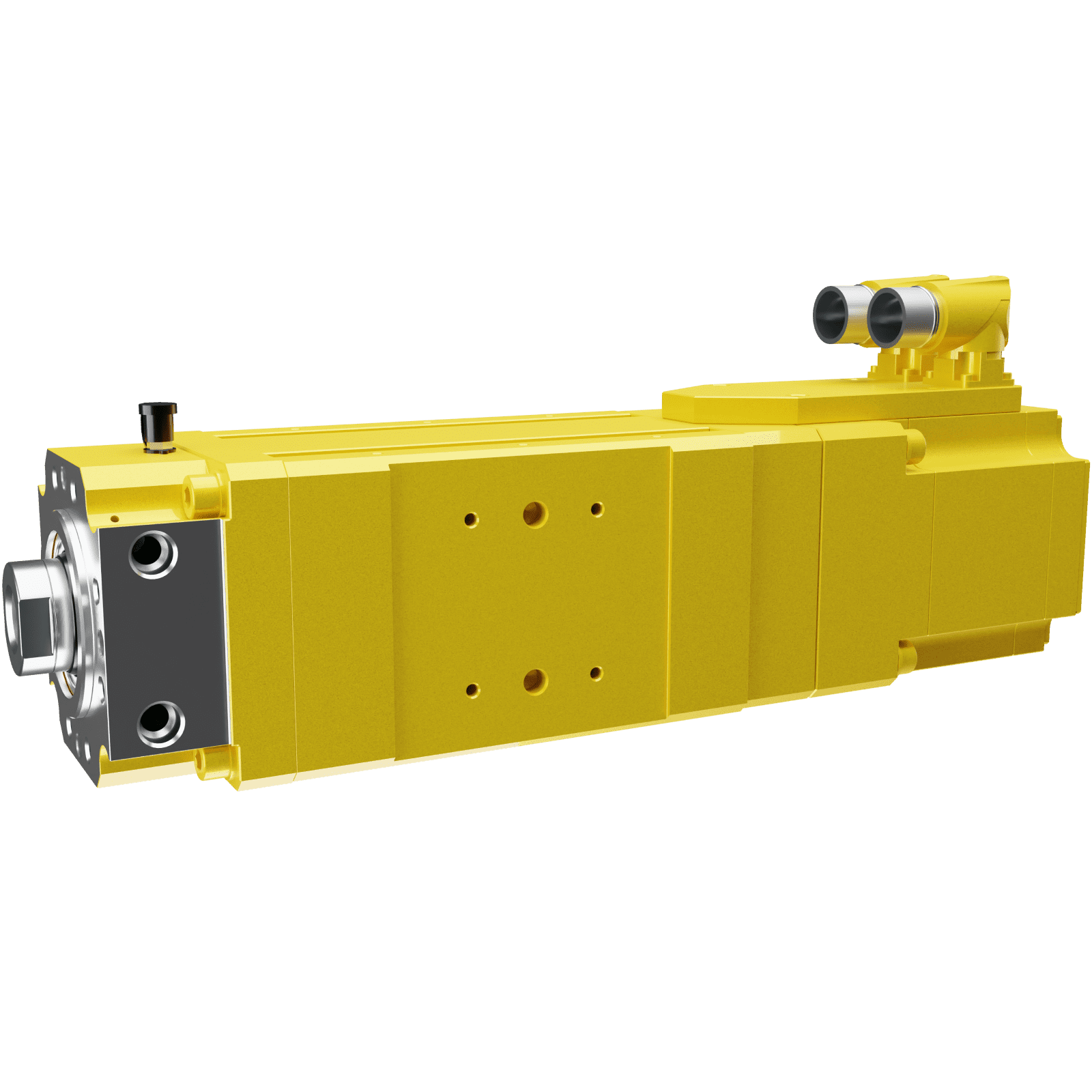

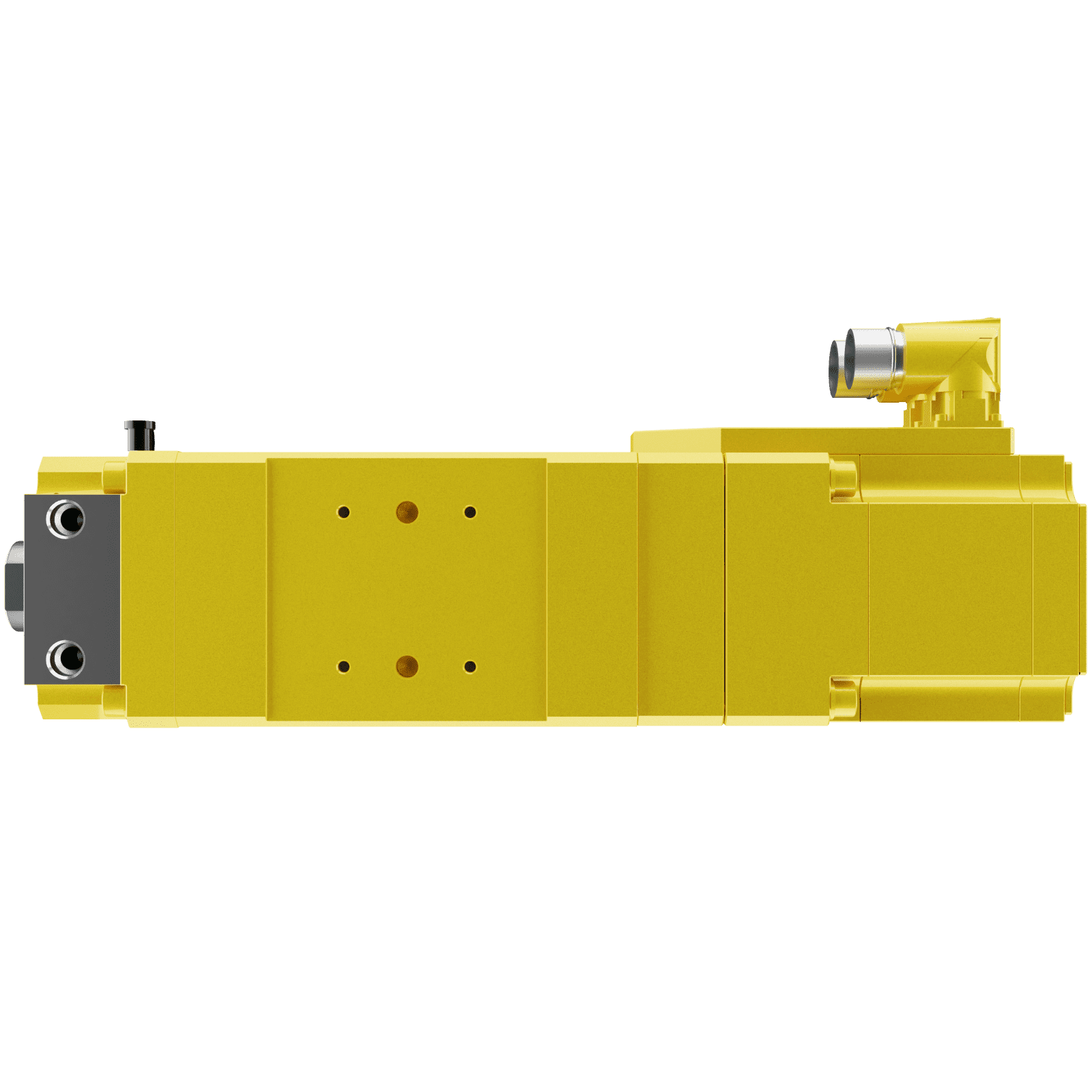

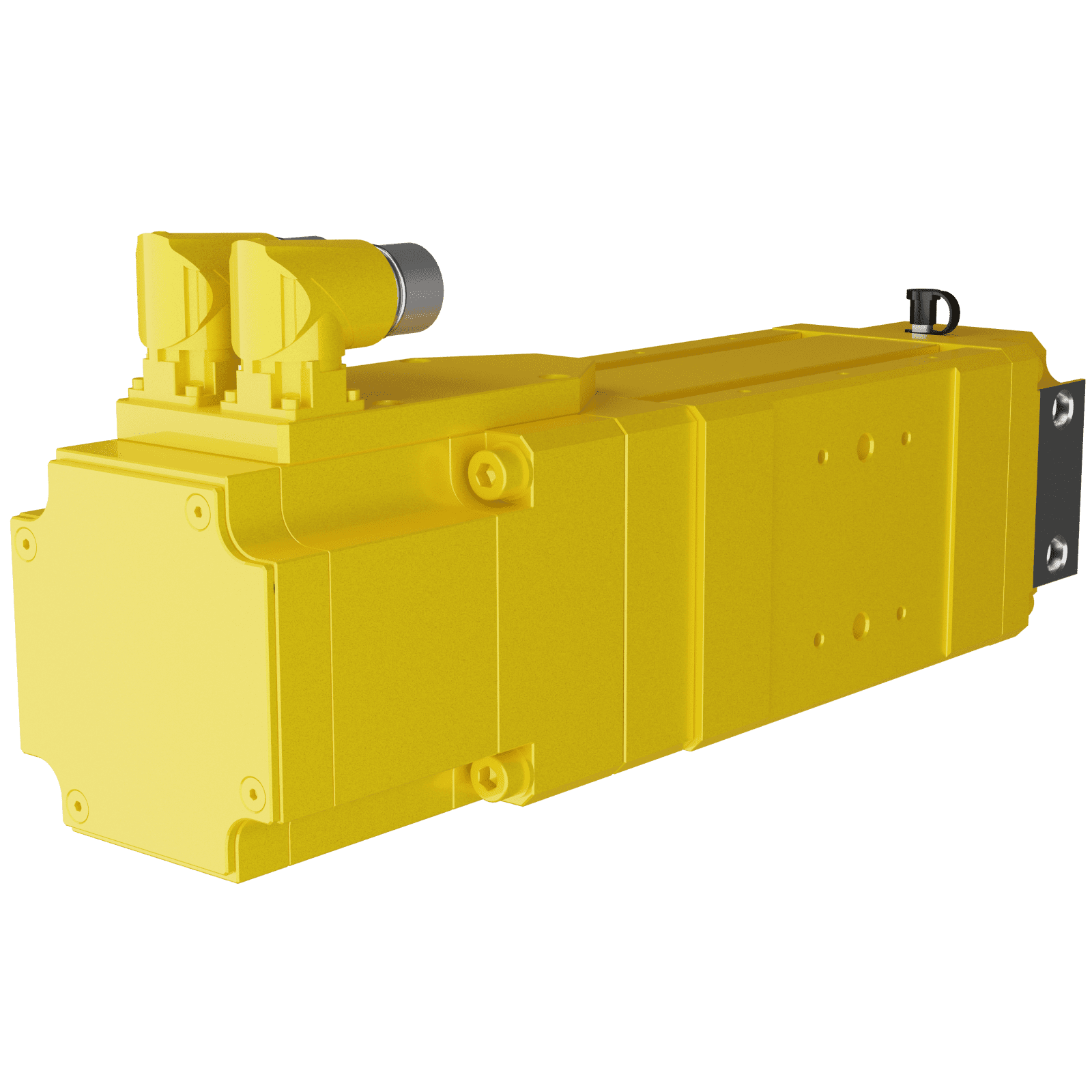

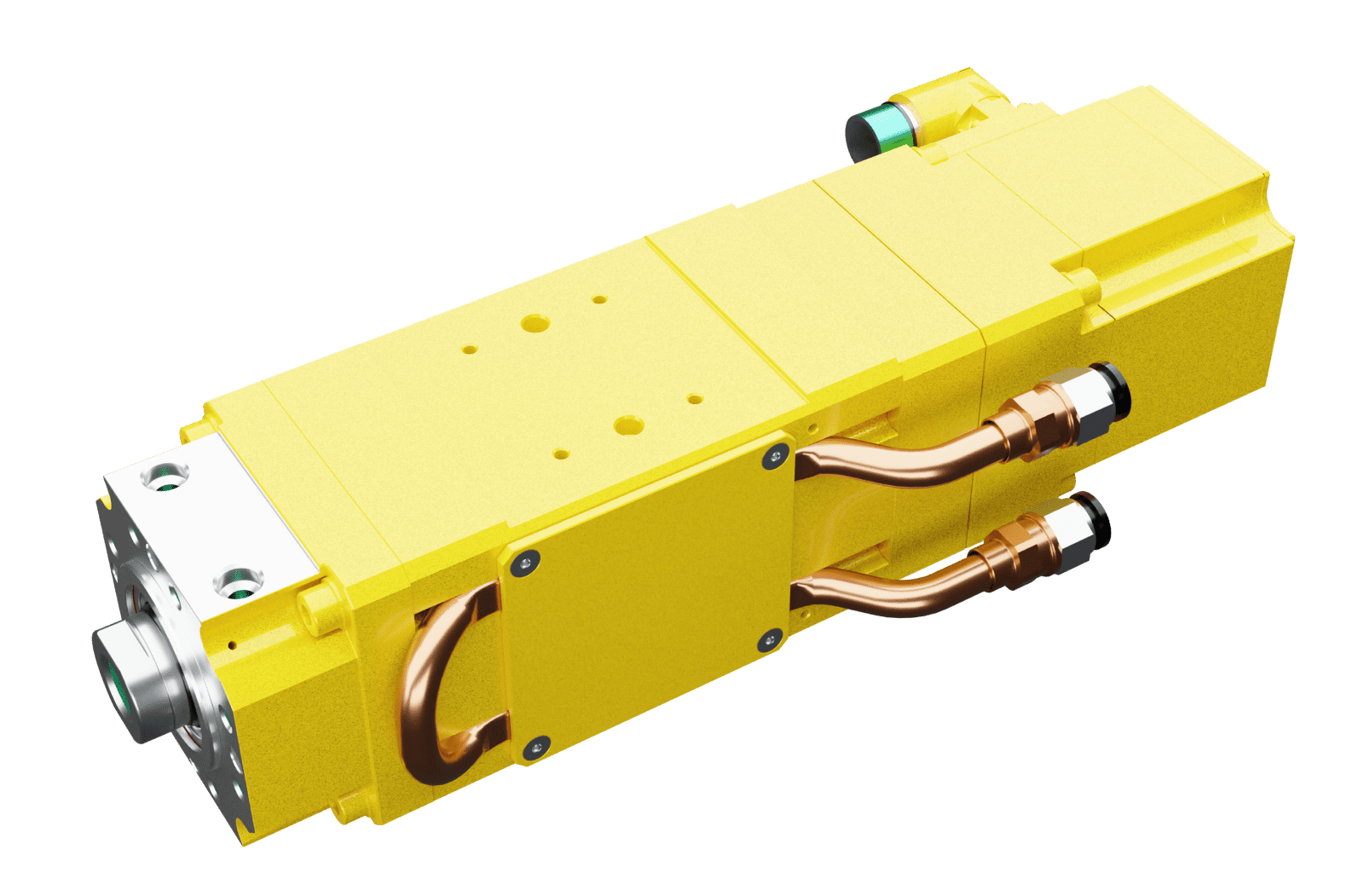

DA 99 Welding Actuator

Heavy-duty servo actuator for spot welding and other industrial applications

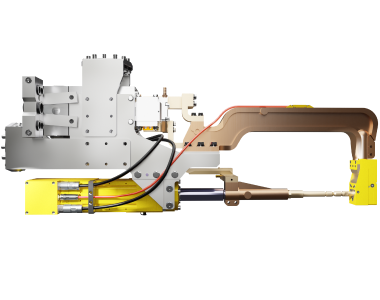

DA99 series roller screw servo actuator is a time proven solution for robotized welding guns (more than 6000 pcs in operation). A powerful 10-pole synchronuous motor, in-house designed and manufactured roller screw and special features ensure high performance, protection against water and welding sludge (IP65) and long service life.

DA99s are compatible with most of industrial robots and control systems, and can be easily installed in any type and model of welding guns. A wide range of options allow to configure the most suitable servo actuator for specific welding cell requirements.

Documents

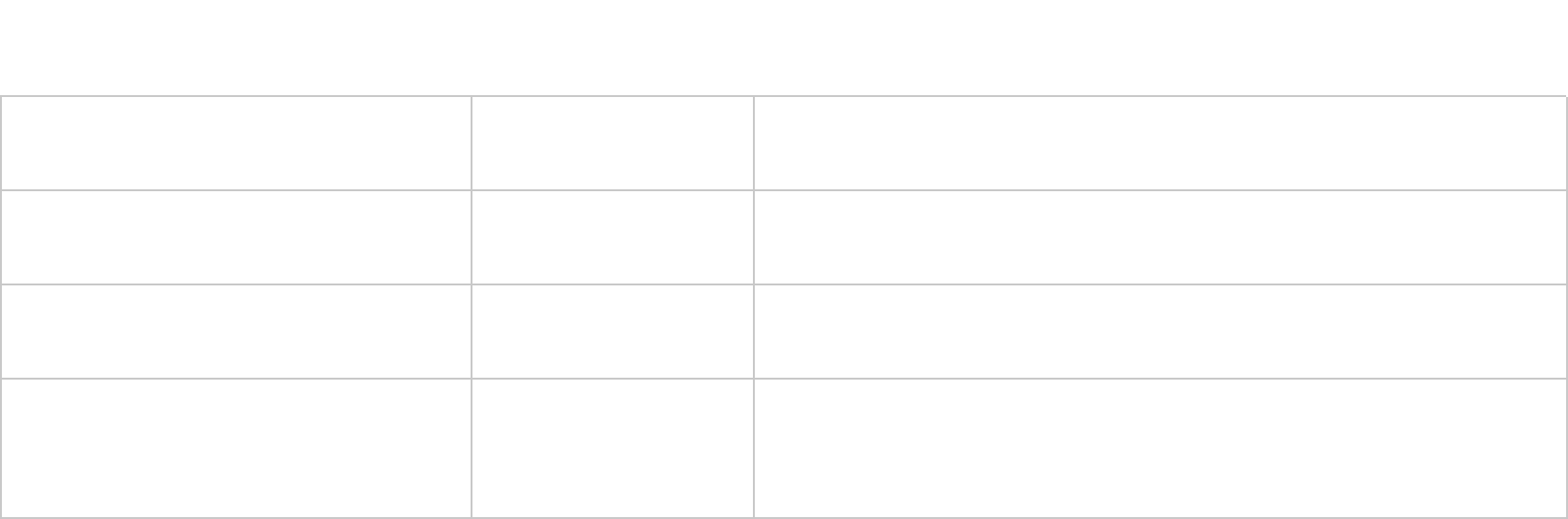

| Model | DA99-W25 | DA99-W212 |

|---|---|---|

| Peak force | 22 000 N | 10 000 N |

| Max. speed | 300 mm/s | 750 mm/s |

| Stroke | 170 mm (option 240 mm) | 170 mm (option 240 mm) |

| Screw lead | 5 mm/rev | 12.5 mm/rev |

| Dynamic load rating | 56 000 N | 30 000 N |

| Basic dimensions | 99x99mm (cross section), 362 mm (length) |

99x99mm (cross section), 362 mm (length) |

| Force repeatability | ±3% | ±3% |

| Base weight | 13.5 kg | 13.5 kg |

| Protection level | IP65 | IP65 |

| Ambience temperature range | 0 to +50°C | 0 to +50°C |

| Service life | 25+ million weld cycles | 25+ million weld cycles |

| Maintenance | grease adding once in 15 million cycles | grease adding once in 15 million cycles |

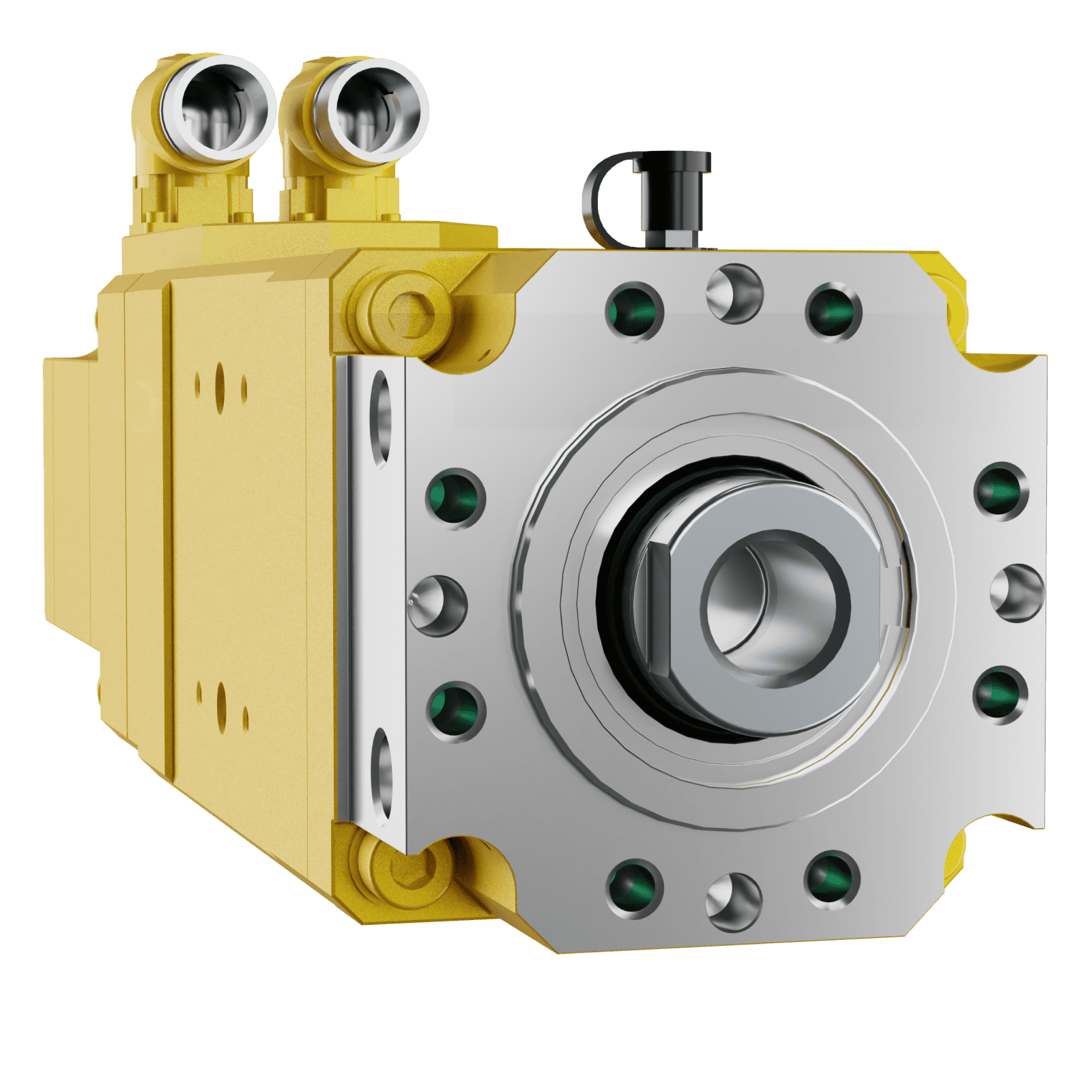

| Mounting | front flange / trunnions / side mounting | front flange / trunnions / side mounting |

| Feedback sensor | depends on robot type: resolver or absolute encoder | depends on robot type: resolver or absolute encoder |

| Voltage | 230V or 400V | 230V or 400V

|

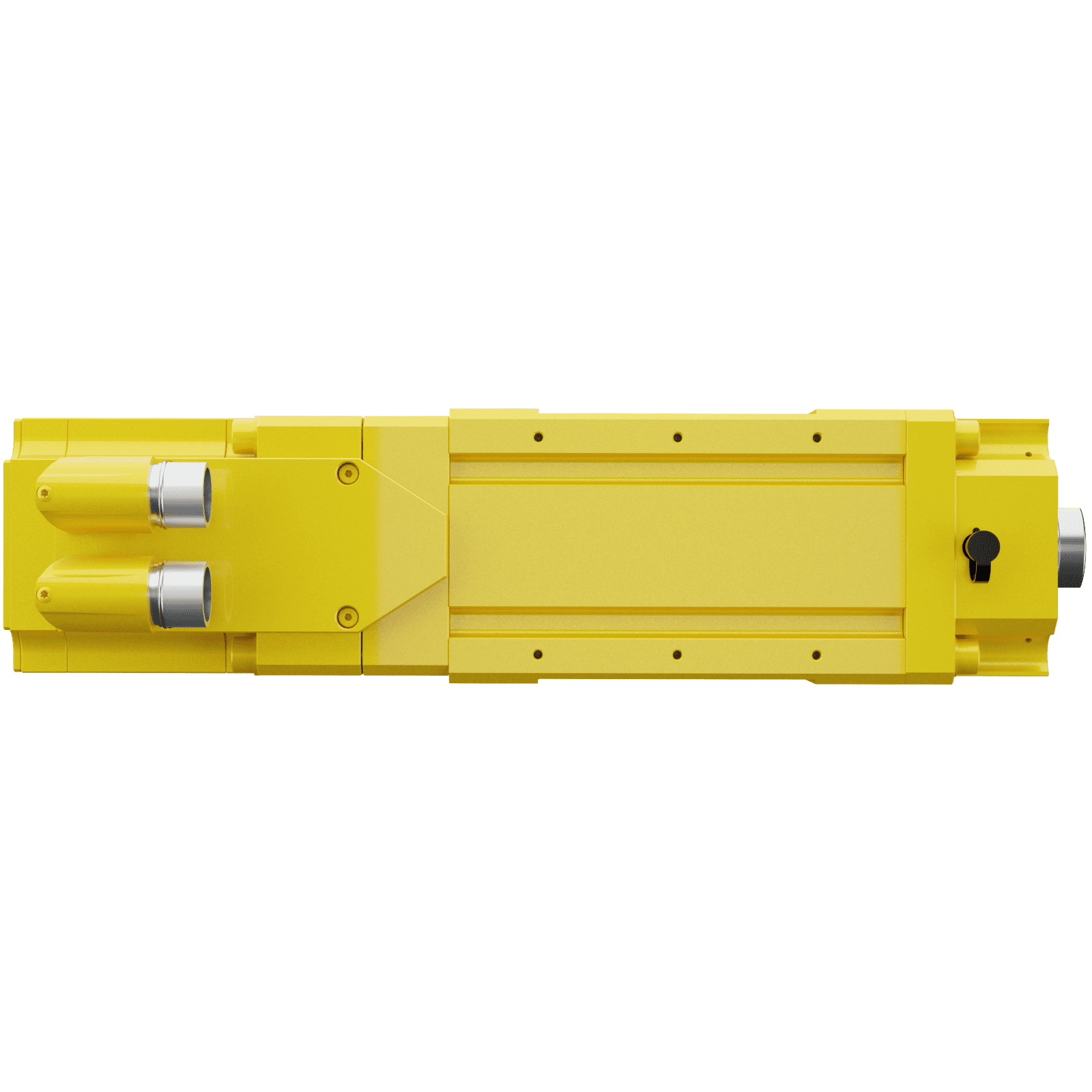

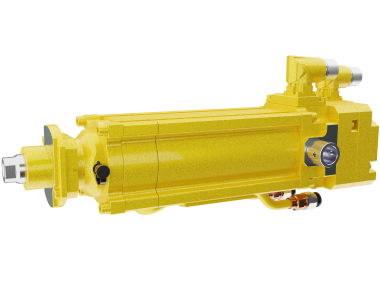

Built-in water cooling circuit enables high performance in the most intense applications with heavy-duty welding cycles (up to 65 welds per minute with 6 kN pressure on the electrodes).

Manual drive option for the electromechanical actuator is designed to facilitate set up processes while power is off when welding gun design does not allow to extend/retract the actuator rod by its direct screwing/unscrewing (for example, when the rod is firmly attached to moveable machine mechanisms).

In this case it is possible to perform tuning of the rod position by applying a wrench towards the manual drive nut in the rear part of the actuator housing.

| Robot Controller Supply Voltage | Robot Controller Model | Robot Control Software | |

| ABB | 400 VAC | IRC 5 | Robot Ware 5, Robot Ware 6 Robot Studio |

| FANUC | 230 VAC (40A or 80A drive) | R-30iA R-30iB R-30iB Plus |

Manual tuning is avaliable (contact Diakont) from V8.20P/43 from V9.10P/16 |

| KUKA | 400/380 VAC KSP/KPP 40A (for other voltages contact Diakont) |

KR C4/KR C5 | KSS 8.3 and higher Add-ons: Torque Control 4.1 and ServoGunBasic 1.0 / 3.0 / 3.1 Kuka System Software: from KSS 8.6 Add-ons: ServoGun Basic 3.1 and newer |

| Yaskawa | 230 VAC | YRC-1000 DX200 |

from YAS2.71.00A from DN2.08.00A |

| Kawasaki | 230 VAC | E52G-A021, E42 (series E2X, E3X, E4X, E5X) |

— |

| Comau | 400 VAC | C5G, C5G Plus |

Motor file is avaliable (contact Diakont) from 4.11.007 |

| Nachi | 230 VAC | FD11 controller with ROX xx2x drive (any ROX drive with third digit = "2") | — |

| Hyundai | 230 VAC | Hi5a-S | — |

1.High performance & welding quality

High speed and acceleration of Diakont electric actuators allow to reduce the time of welding gun opening and closing. A specially designed 10-pole synchronous motor allows performing more welding spots without overheating compared with competitors. DA99 Diakont actuator can make 30 welds/minute at high force without need for additional cooling.

2.Robust design and reliability

The special in-house design and manufacturing of Diakont actuators and its components, from roller-screw to the housing allows to keep the quality at high level ensuring stable operation even at stressful requirements.

3.Best-in-class lifetime

Integrated and robust design of Diakont roller-screws and special know-how technologies of metal hardening provide our products with exquisite lifetime characteristics capable of bearing over 30 million weld cycles.

4.Simple maintenance

Diakont servo actuators save time on maintenance not only because of their high quality and reliability. Such a simple procedure as grease adding can also be done very easy through a zerk on the housing and requires to be done only once in 15 million cycles.

Do you have questions about our solutions or need personal advice? Take advantage of our many years of experience, the high technical competence of our team and our wide range of services.