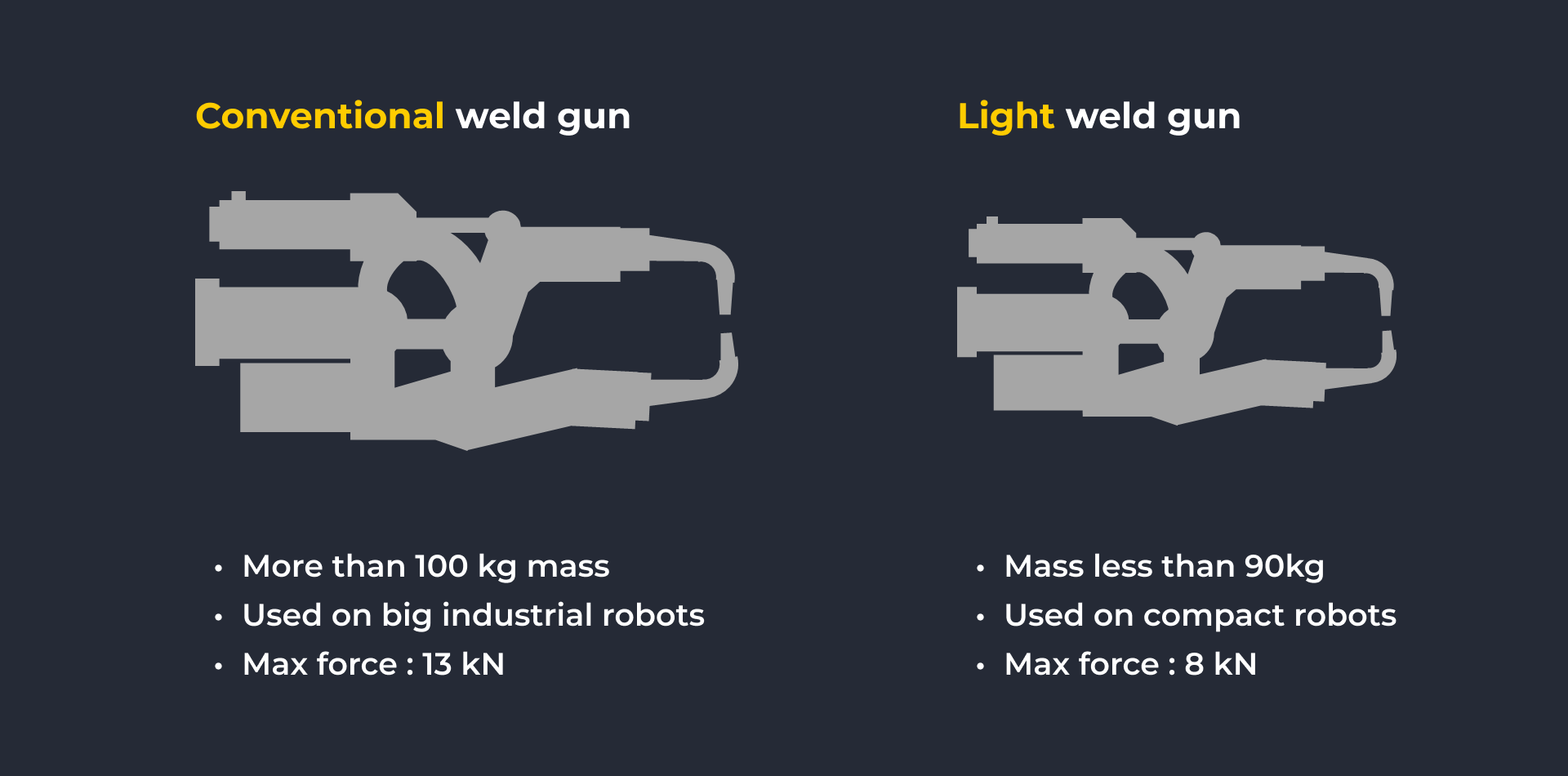

As for most of the spot welding programs 8 kN force is sufficient to produce good quality spot welds, automotive manufacturers tend to equip their manufacturing facilities with light weld gun solutions. What can be not obvious from the beginning is the positive effect for the manufacturing – higher robot dynamics can be achieved! As the gun itself has comparable parameters of closing/opening speeds and force, it can be used for the same applications, but at a much higher pace: there is less stress on robot moving mechanisms, so higher accelerations and speeds can be allowed when carrying the lightweight guns. This can have a good effect on the welding cell productivity.

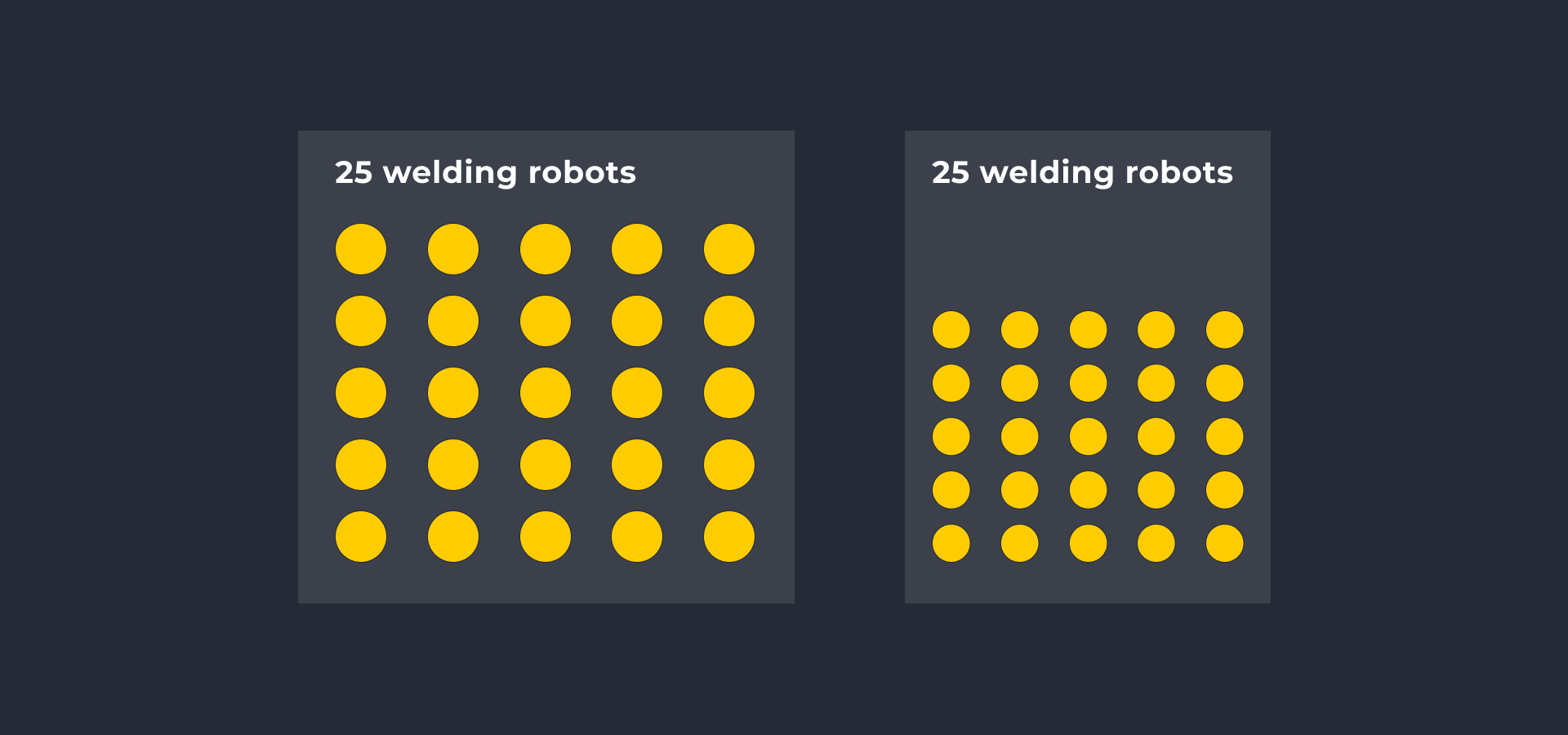

There are several economical advantages of equipping welding cells with smaller industrial robots. Besides the costs of the light weld gun itself, the robot also costs less, so the initial investments will be lower. Additionally, smaller robots consume less energy, what can have a positive effect on the ownership costs of the welding cell.

What is even more interesting is that if properly organized at the design stage of the new facility, it is possible to save substantial amount of space. First of all, it is less construction costs less rent and all the initial investments. Secondly, it is less variable costs during the line lifetime, e.g. energy costs for heating of the plant would also be lower.