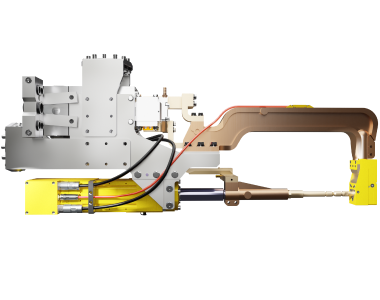

Resistance spot welding is one of the most efficient joining technologies in the automotive industry, where high repeatability and the ability to automate are must-to-haves in metal joining processes.

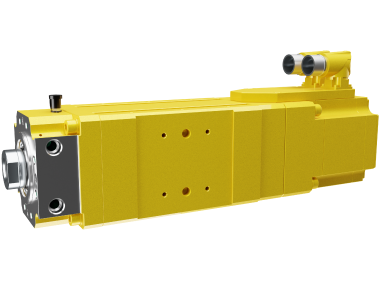

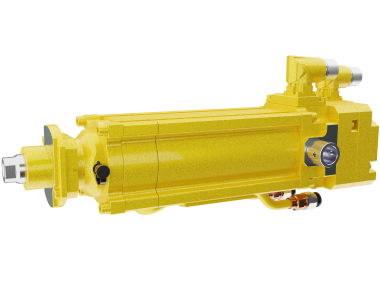

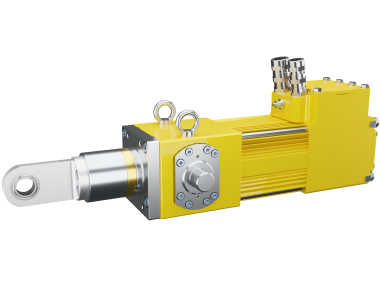

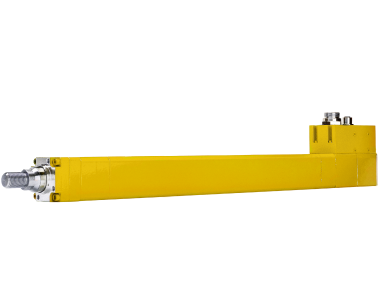

Application of roller screw actuators of our own design and robotized technologies for their manufacturing allows Diakont to provide stable quality and unsurpassed reliability of the manufactured servo actuators at the best market price

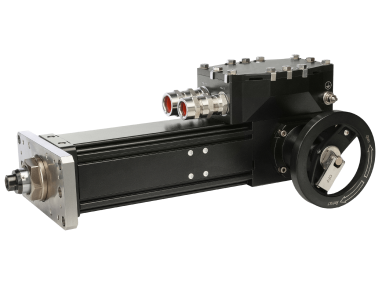

To expand the capabilities of plastic machinery leading companies are increasingly switching their machinery from traditional hydraulics and pneumatics to electric actuators.

Electric actuators control the positioning, speed and force profile of mechanisms inside molding machines and molds more precise, that enable producing technologically more complicated products, reducing maintenance costs and not harming the environment in comparison with hydraulic cylinders.

Diakont manufactures roller-screw electric actuators for shot-meters that combine high precision, long lifetime and high force in compact footprint.

Electric actuators are used in dispensing systems to ensure high accuracy and repeatability of the adhesive and sealant dosing process. The smaller the electric actuator is, the more compact shot-meter can be designed.

Actuators are critical for turbine operation parameters. The use of Diakont roller screw actuators enables to improve efficiency of turbine control, simplify a control system and reduce maintenance requirements.